| Brand |

Mas |

|---|---|

| Manufacturing Country |

China |

| Maximum workpiece width |

330 mm |

| Maximum workpiece height |

100 mm |

| Spindle shaft diameter |

35 mm |

| Blade diameter |

305 mm |

| Spindle speed |

5500 rpm |

| Blade speed |

2880 rpm |

| Work table dimensions |

340 x 500 mm |

| Air consumption |

0.6 MPa, 6 bar |

| Blade motor power |

3 kW (4 HP) |

| Spidnles power |

7.5 kw |

| Total power |

10.5 kw |

| Mininum number of operators |

1 number |

| Weight |

500 kg |

| Dimensions |

1640*1320*1980 mm |

Be the first to review “Finger Joint MAS MXB3510R” Cancel reply

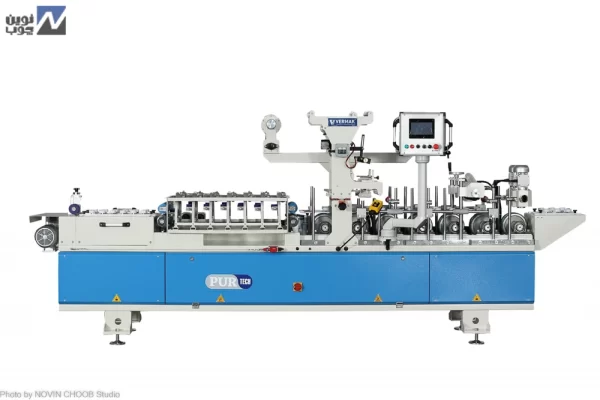

This product produced by the MAS company of China, which is exclusively offered in Iran by "Novin Chub Group", is made entirely of high-quality parts. The technical specialists of Novin Choub Company, who have attended the training courses organized by the company in China under the supervision of the designers and technicians of MAS Company, will be ready to perform necessary repairs and services on the purchased devices in case of any technical problems. give In addition, used machinery is also offered to customers with quality assurance from Novin Chub company. If you are planning to buy a cnc bandsaw, we suggest you to view the cnc bandsaw purchase page to get to know all the models of this woodworking machine. Due to the high precision of this machine in cutting and also the elimination of human error that always occurs while working with a normal chainsaw, completely identical cuts are made on the wood pieces, and after that, connecting the same pieces to each other will produce completely identical products. ended From the results of identical cuts created by the massive but at the same time delicate cnc band saw machine, it is very important to mention that after the cutting stage is completed, the need to sand the cut parts is eliminated, which itself guarantees an increase in the speed of the process. Production by eliminating one of the former time-consuming and precise steps. No need for sanding also means no need for special tools and in fact no need to invest in such devices and reduce production costs. On the other hand, the amount of wood waste produced during the production process - due to the same cuts made on wood pieces - is also minimized; As a result, a significant part of the production costs has been significantly reduced and it provides the possibility of creating a greater profit margin for managers, investors and producers. With a little reflection and examination of the features and benefits of this device, it will be clear that investing in this device and using it in the field of mass production in the long and short term is a logical and at the same time economic decision; Because with the use of this MAS MJ359 CNC table saw, production costs and limitations have been minimized, and in competition with other manufacturers, higher and uniform quality of products, minimal waste production, and maximum increase in production process speed are undeniable advantages. will be considered

Reviews

There are no reviews yet.